DB2

The engine was inspected the engine and required work being carried out.

Removal of the sump etc to investigate engine internals. We found nice billet crankshaft but standard rods and bearing cheeses. Decided further investigation was needed.

Head removed, revealing nice Omega pistons.

Front crankshaft main journal showing damage. On further investigation, it was found this journal had been ground incorrectly. Luckily the crank polished up to the correct size, with no further damage found.

Engine and front suspension components ready for reassembly.

Head reassembled after machining and all valve clearances set and decoked.

Engine ancillaries cleaned and painted. Carburetors fully rebuilt with new spindles and bushes, along with new inlet manifolds. All ready for assembly.

Crank refitted with new solid cheeses and new I-Beam conrods.

Top of the block showing the original Omega pistons back in place.

Lower timing chains and tensioner in place, along with replacement top timing chain tensioner for the later short cam chain set up.

On dismantling, found it had the early/Lagonda type top timing chain system. This will be changed for the later shorter chain set up on the rebuild.

Poor condition of the front main crankshaft bearing.

Damaged caused by poor original casting of the cylinder head on the exhaust side. The head has been machined to remove the damage and is all ok in all other respects.

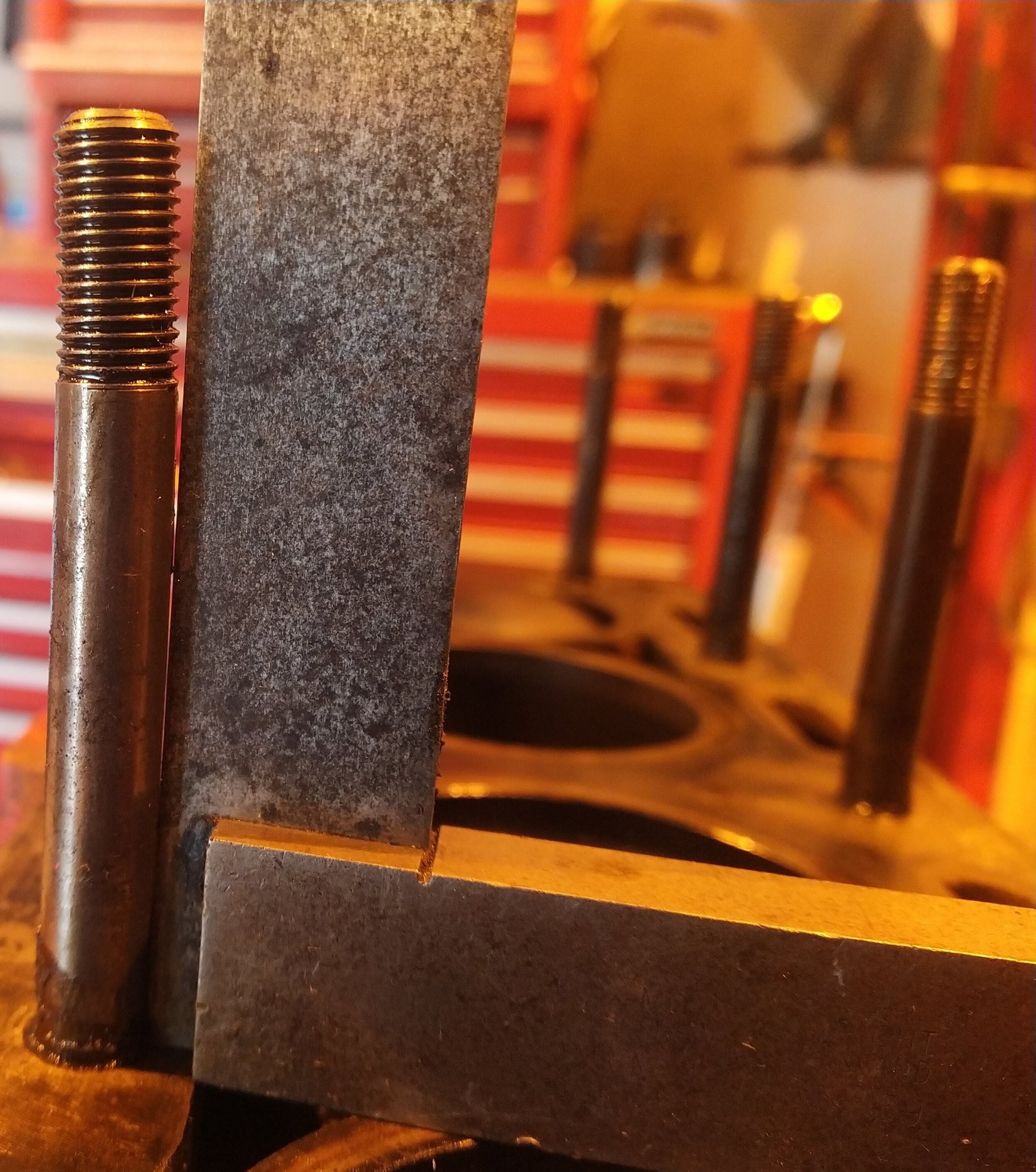

A bent cylinder head stud caused by the faulty head casting. This had happened to three studs on the exhaust side. It made getting the head off a bit awkward!

Cylinder block in engine stand ready for assembly to start.

Original Omega pistons cleaned and new con rods ready for assembly.

New oil pump and original oil pick up in place along with oil pump jack shaft.